全站搜索

Search the entire website

Search the entire website

Professional escort, your trusted choice

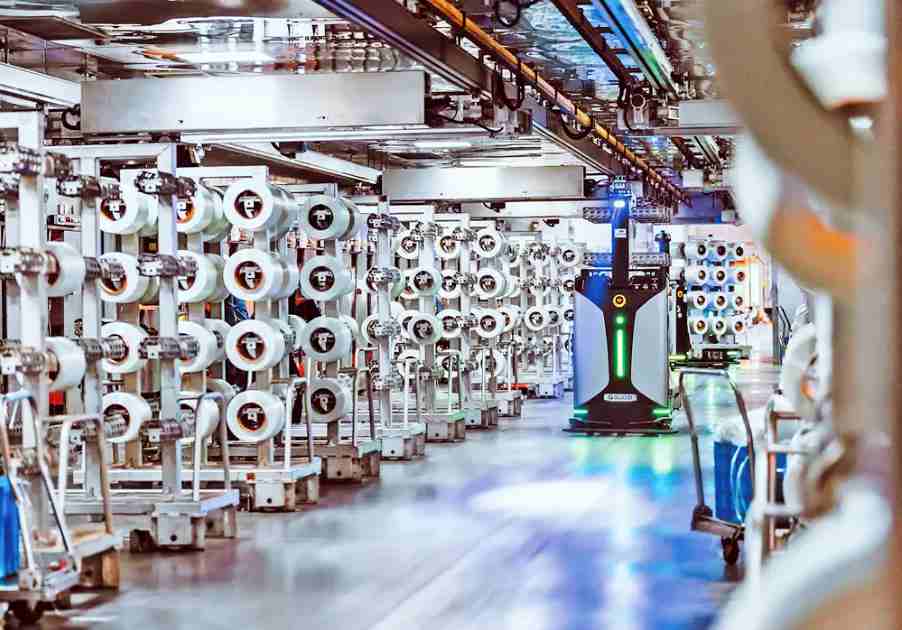

How can traditional fiberglass enterprises transform? When executives from a glass fiber grid cloth manufacturer explored AI at an industry summit, they faced common challenges in traditional manufacturing. This guide provides a practical combat path from AI obstacles to a functional smart factory.

STEP 1: Focus on High-Value Scenarios

Start with areas where data is more accessible:

STEP 2: Build a Solid Data Foundation

STEP 3: Validate with Small-Scale Pilots

One manufacturer’s pilot results:

STEP 4: Avoid Vendor Pitfalls

Beware of “one-size-fits-all” solutions:

STEP 5: Develop Talent In-House

Cost-effective training:

| Traditional Pitfall | Solution | Case Study |

|---|---|---|

| Aiming for “full smartness” | Start with single-point breakthroughs like inspection | One factory achieved 230% ROI on AI inspection |

| Relying only on external IT | Grow internal “AI translator” roles | Process engineers learning Python |

| Neglecting data management | Treat production data as an asset | Build a database for fiber drawing parameters |

For a glass fiber grid cloth plant, using AI to reduce fiber breakage by 18% saves costs. It also builds a reputation for reliable supply in competitive markets like wind energy.

The core of smart upgrading is transforming experienced craftsmanship into scalable digital assets.

Discover how China’s green development leverages eco-materials like fiberglass mesh and roving yarn in global sustainability projects. Explore innovations from mesh manufacturers and roving composites in solar/wind applications – actionable models...

查看全文The latest economic data reveals China's steady progress in innovation-driven growth. Interior and exterior fiberglass mesh manufacturers are at the forefront of this transformation. Strategic emerging industries and increased corporate investme...

查看全文Traditional industries form the foundation of China's manufacturing sector. They account for about 80% of added value and employment. Their transformation is crucial for building a modern industrial system. Upgrading towards high-end, smart, and ...

查看全文Customs data shows sustained growth in China's foreign trade, driven by private enterprises, emerging markets, and "new trio" products. Fiberglass mesh manufacturers expand globally with innovative offerings, showcasing the resilience of Chinese m...

查看全文