全站搜索

Search the entire website

Search the entire website

Professional escort, your trusted choice

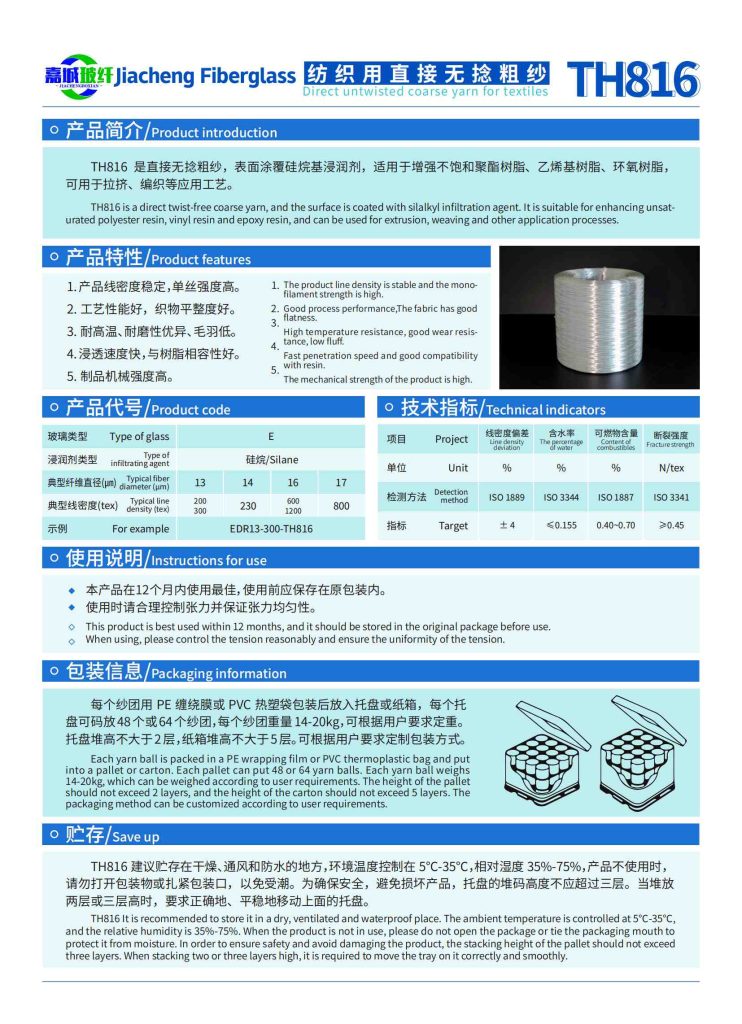

TH816 是一款表面涂覆硅烷基浸润剂的直接无捻粗纱,专为增强不饱和聚酯树脂、乙烯基树脂及环氧树脂设计,适用于拉挤成型、编织等多种工艺。其优异的兼容性与机械性能,使其成为建筑加固、航空航天、新能源等领域的理想选择。

| 分类 | 参数细节 |

|---|---|

| 玻璃类型 | E玻璃 |

| 浸润剂类型 | 硅烷基浸润剂 |

| 纤维直径(μm) | 13、14、16、17(可选) |

| 线密度(tex) | 200、230、600、800(支持定制) |

| 示例型号 | EDR13-300-TH816 |

| 检测项目 | 单位 | 标准方法 | 指标范围 |

|---|---|---|---|

| 线密度偏差 | % | ISO 1889 | ±4 |

| 含水率 | % | ISO 3344 | ≤0.155 |

| 可燃物含量 | % | ISO 1887 | 0.40~0.70 |

| 断裂强度 | N/tex | ISO 3341 | ≥0.45 |

TH816 无捻粗纱广泛用于:

支持定制线密度与包装方案,提供技术咨询与物流保障,助力网格布厂家及无捻粗纱供应商高效对接下游需求。

直接无捻粗纱、玻纤网格布、玻璃纤维直纺纱、无捻粗纱供应商、TH816硅烷浸润剂、高强复合材料、网格布生产定制。

文档说明:以上信息基于产品技术参数整理,实际应用需结合具体工艺条件调整。

Technical Document for Direct Untwisted Coarse Yarn TH816 for Textile Use

TH816 is a direct untwisted coarse yarn coated with a silane-based sizing agent, designed to enhance unsaturated polyester resin, vinyl resin, and epoxy resin. It is suitable for pultrusion, weaving, and other application processes. With excellent compatibility and mechanical properties, TH816 is an ideal choice for construction reinforcement, aerospace, new energy, and related fields.

| Category | Details |

|---|---|

| Glass Type | E-Glass |

| Sizing Agent Type | Silane-based |

| Fiber Diameter (μm) | 13, 14, 16, 17 (optional) |

| Linear Density (tex) | 200, 230, 600, 800 (customizable) |

| Example Model | EDR13-300-TH816 |

| Test Item | Unit | Standard Method | Target Range |

|---|---|---|---|

| Linear Density Deviation | % | ISO 1889 | ±4 |

| Moisture Content | % | ISO 3344 | ≤0.155 |

| Combustible Content | % | ISO 1887 | 0.40~0.70 |

| Breaking Strength | N/tex | ISO 3341 | ≥0.45 |

TH816 untwisted coarse yarn is widely used in:

Customized linear density and packaging solutions available. Technical consultation and logistics support provided to help fiberglass mesh manufacturers and untwisted coarse yarn suppliers efficiently meet downstream demands.

Direct untwisted coarse yarn, fiberglass mesh, fiberglass yarn, untwisted coarse yarn supplier, TH816 silane sizing agent, high-strength composites, custom fiberglass mesh production.

Document Note: The above information is based on product technical parameters. Actual applications may require adjustments according to specific process conditions.

在建筑外墙加固、内墙防裂的战场上,玻璃纤维网格布是当之无愧的隐形卫士。但您是否好奇,一张高性能网格布的背后,究竟藏着哪些核心材料密码?作为深耕行业多年的网格布厂家,今天我们将揭开高品质网格布背后的原料真相——玻璃纤维纱与无捻粗纱,正是它们决定了产品...

查看全文深度解析AI如何驱动电子纱产业升级!了解高端电子布(超薄、低介电)在5G/服务器中的关键作用,国产玻纤龙头(中国巨石、泰山玻纤等)技术突破与产能布局,以及网格布厂家、无捻粗纱市场趋势。把握高频高速PCB需求爆发下的投资机遇。

查看全文探索新思想如何引领高质量供给创造新需求!了解供给侧改革成效、消费品创新爆发(年增品种超809万)、AI与柔性生产变革,以及玻纤网格布、玻璃纤维纱、无捻粗纱等关键材料如何赋能产业升级与国家战略。获取“三品”战略最新动向与投资赛道洞察。

查看全文当人工智能的浪潮席卷全球,一个关键问题日益凸显:这场革命将缩小还是扩大发展鸿沟?国际货币基金组织的数据触目惊心——发达国家AI准备指数高达0.68,而新兴国家和低收入国家仅为0.46和0.32。技术差距犹如无形的墙,但中国提出的“智能向善”理念,正为世界推开一扇平...

查看全文